Commend

-

Rubber pad bonding machine

Used for sticking the sealing rubber ring on the iron cover, with double stations, high efficiency, simple operation (needs to be connected to an air pump or air compressor).

- Power supply: 220V/50Hz

- Equipment weight: 130KGS

- Dimensions: 1000*700*1000mm

-

PU glue injection machine with one stations

This glue injection machine has the functions of automatic feeding, self-circulation, and automatic heating. It has three raw material tanks and one cleaning tank, all made of 3mm thick stainless steel. The glue head can move parallelly and has built-in storage memory. It can record more than 2000 mold glue weights. It has high production efficiency, simple and reliable operation, accurate glue output, stable and durable.

- Maximum working diameter: 400mm

- Temperature control: 0-190℃

- Glue output: 15-50g

- Total power: 30KW

- Air pressure: 0.6MPa

- Power supply: 380V/50HZ

- Equipment weight: 950KGS

- Dimensions: 1700mm*1700mm*1900mm

-

End cover glue injection machine

This glue injection machine can be equipped with a variety of flowable glue ratios such as 1:5, 1:8, 1:6, etc. It has a servo motor, is precise and efficient, stable and durable, and is widely used in the field of filter element glue ratio.

- Glue output: 5-40g

- End cover diameter range: 70-420mm

- Production efficiency: 8pcs/min-20pcs/min (depending on the product)

- Total power: 5KW

- Air pressure: 0.6Mpa

- Power supply: 380V/50HZ

- Equipment weight: 350KGS

- Dimensions: 1100mm*1100mm*1700mm

-

Full-auto 60 stations U-type curing oven line

It is mainly used for curing after the injection machine injects the mold glue. The normal curing time at room temperature is about 10 minutes (when the glue is at 35 degrees and under pressure). The production line completes curing after rotating for one cycle. This can reduce the time workers spend on handling and greatly improve efficiency.

- Rotation speed: 10-15min/rotation

- Temperature: 45 degrees adjustable

- Heating power: 15KW

- Air pressure: 0.2-0.3Mpa

- Number of stations: 60

- Output: 5000pcs/shift

- Max height: 350mm

- Equipment weight: 620KGS

-

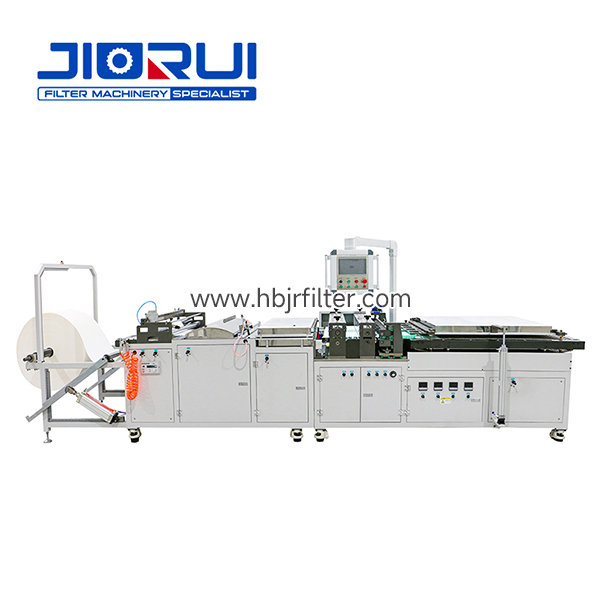

Rotary type air filter paper folding machine

Drum-type air filter folding machine 700 model: This machine has the functions of automatic paper feeding, pneumatic cutting, counting, humidifying, preheating, suspended folding, automatic collection and transfer, chain transmission, heating and shaping to make the paper form in one go.

Automatically adjust tension, automatically adjust the direction of the receiving pulley, and adjust the distance and height.

- Type: ZZ-700-6

- Working speed: 120m/min

- Paper width: 100-700mm

- Roller specifications: can be customized

- Folding height: 22mm-72mm

- Temperature control: 0-190℃

- Total power: 18KW

- Air pressure: 0.6Mpa

- Power supply: 380V/50HZ

- Dimensions: 2880mm*1350mm*1750mm(900KGS)2480mm*1350mm*2050mm(1420KGS)

-

Spiral tube making machine

This machine is mainly used for making inner and outer nets of filter elements. It can be coiled in a spiral curling way and can be coiled in two ways: punched net belt and drawn net belt. The net belt width is 109mm and needs to be connected to an air pump or air compressor.

Automatically adjust the angle and cutter (no need to change the mold)

- Type: LXW-109-5

- Diameter: 80-450mm

- Net width: 109mm

- Net thickness: 0.5-0.8mm

- Minimum length of roll net: 170mm

- Production speed: 54m/min

- Total power: 4KW

- Air pressure: 0.6MPa

- Power supply: 220V/50 HZ

- Equipment weight: 900KGS

- Dimensions: 1400*1200*1780mm

-

Rotary type air filter paper folding machine

Drum-type air filter folding paper machine Model 700: This machine has functions such as automatic paper feeding, pneumatic cutting, counting, humidifying, preheating, automatic winding, chain conveyor, heating and shaping, so that the paper can be formed once.

- Type: ZZ-700-5

- Working speed: 75m/min

- Origami width: 100-700mm

- Roller specifications: can be customized

- Folding height: 22-72mm

- Temperature control: 0-190℃

- Total power: 15KW

- Air pressure: 0.6Mpa

- Power supply: 380V/50HZ

- Dimensions: 2400mm*1300mm*1400mm(800KGS) 1850mm*1300mm*1300mm(1025KGS)

-

Automatic air filter paper filling machine

Installed at the end of the folding machine, it is used to spiral coil the folded filter paper and load it into the net in one go.

- Type: ZWJ-5-1000

- Working diameter: 230mm-350mm

- Production efficiency: 2pcs/min

- Height: 380-1000mm

- Air pressure: 0.6Mpa

- Power supply: 380V/50HZ

- Dimensions: 2100mm*2050mm*1450mm(530KGS)1600mm*650mm*1850mm(240KGS)

-

Inner core filter paper folding machine

Inner core folding machine: mainly has cutting, humidifying, upper and lower heating and shaping, adjustable speed, counting, drawing lines and other functions. It is mainly used for folding the inner core paper of large vehicle air filters.

- Type: NX-5-600

- Working speed: 15-30m/min

- Paper width: 100-590mm

- Folding height: 9-25mm

- Roller specifications: can be customized

- Temperature control: 0-190℃

- Total power: 8KW

- Air pressure: 0.6MPa

- Power supply: 380V/50HZ

- Equipment weight: 450KGS

- Dimensions: 3300mm*1000mm*1100mm