Introduction to spiral tube making machine - your solution for filter element production

Are you in the filter element manufacturing business? Do you need a reliable, efficient machine for the production of inner and outer meshes for filter elements? Look no further because our air filter making machine can meet your production needs.

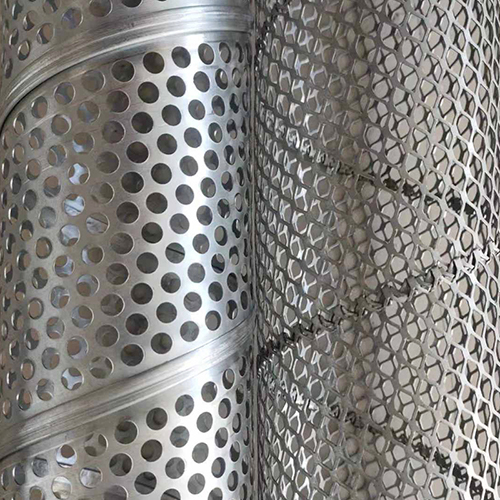

A spiral crimping machine is a specialized piece of equipment designed to manufacture the inner and outer mesh of filter elements using the spiral crimping process. This innovative machine is the perfect solution for companies looking to streamline their filter element production processes and achieve consistent, high-quality results.

Main features and benefits:

1. Spiral crimping technology: This machine adopts spiral crimping technology to ensure accurate and uniform crimping of raw materials. This results in a tight, secure fit that provides excellent structural integrity to the filter element mesh.

2. Universal raw materials: The screw crimping machine is compatible with a variety of raw materials, including punching mesh belts and tensile mesh belts. This versatility allows you to adapt to different production requirements and material preferences.

3. Efficient operation: With its advanced design and engineering, this machine delivers efficient and reliable performance, allowing you to meet production goals and deadlines with ease.

4. Compatibility with air pump or air compressor: The machine can be easily integrated with an air pump or air compressor to provide the necessary pneumatic power for smooth and consistent operation.

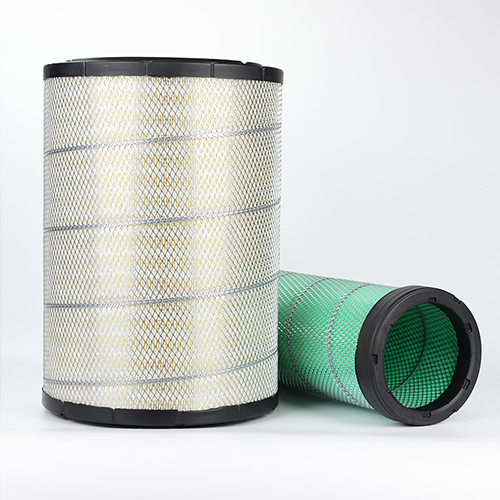

5. Customizable output: Whether you need to produce different sizes or specifications of filter mesh, the machine can be adjusted to suit different production requirements, providing flexibility and customization options.

6. Quality Assurance: By using a spiral crimping machine, you can ensure that your filter mesh is manufactured with precision and accuracy to meet the highest quality standards and customer expectations.

7. User-friendly design: The machine was designed with user convenience in mind, featuring intuitive controls and easy maintenance, making it suitable for operators of different skill levels.

application:

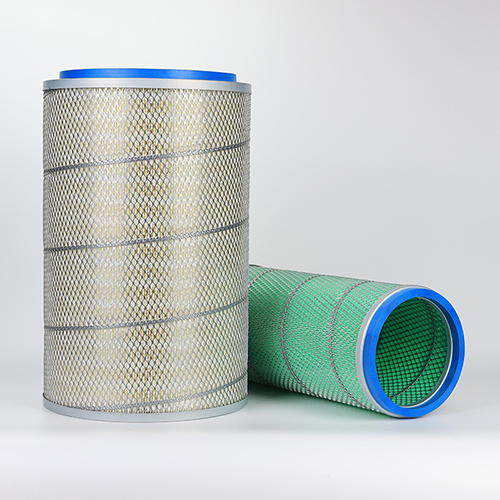

Spiral crimping machines are ideal for companies producing filter elements for a variety of applications, including air filtration, water purification, automotive, industrial, and more. Whether you are a small manufacturer or a large industrial enterprise, this machine can meet your specific production needs.

In summary, the screw crimping machine is a reliable and efficient solution for the production of inner and outer meshes of filter elements. Its advanced technology, versatility and user-friendly design make it a valuable asset for businesses looking to optimize their filter element production processes.

Invest in a screw crimping machine to take your filter manufacturing to the next level. Experience the benefits of increased efficiency, quality and customization in one powerful machine. Contact us today to learn more about how a spiral crimping machine can improve your production capabilities.

Post time: Aug-13-2024