The mesh spot welding machine

Key Electrical Components Brand

Electrical motor: VEICHI

Frequency converter: VEICHI

Low voltage component: DELIXI

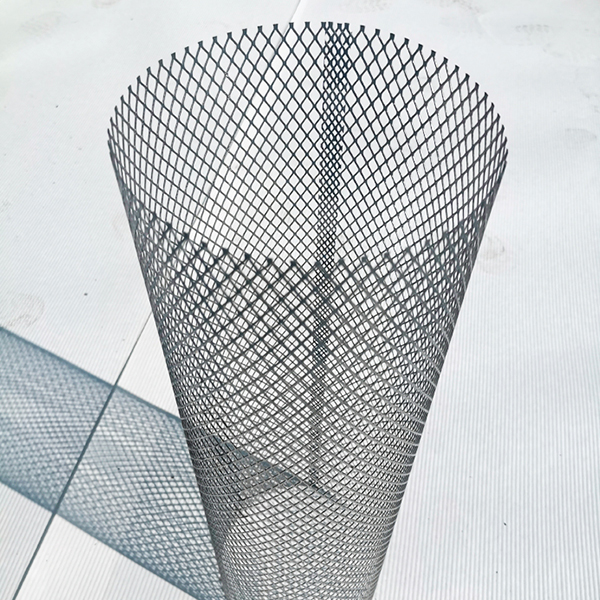

Finished Products

Product Features

Introducing our latest high-efficiency equipment, specialized in spot welding large air filter outer and inner screens. This innovative cutting-edge machine has been designed primarily to provide the best solution when it comes to welding large air filters safely and efficiently.

Our equipment is designed with state-of-the-art technology to meet exactly your needs. It is ideal for industrial use as the machine can withstand harsh use. The construction materials used to build the unit are strong and durable, ensuring it will last for many years.

Spot welding is a welding technique that involves joining two metal surfaces through the application of pressure and heat. Use this technique when welding requires high precision. The device is designed to help the user achieve the desired welding results as it is designed to facilitate high speed spot welding without the use of any additional hand tools.

Large air filter outer and inner screens require a lot of force and pressure to weld accurately; our equipment has specialized sensors that adjust the pressure to ensure optimal welding results. This feature allows the operator to use the machine safely. Sensors allow easy control of the welding process for optimal results.

In conclusion, our equipment is the solution for all your air filter welding requirements. Whether you operate a large industrial facility or a small shop, our cutting-edge equipment is ideal for welding large air filter outer and inner webs with precision and speed. Plus, the durable construction ensures a longer machine life. Why not try our equipment today and experience the best spot welding technology at your fingertips.

Application

Used in the production of truck air filters, hydraulic oil filters, dust collecting filters